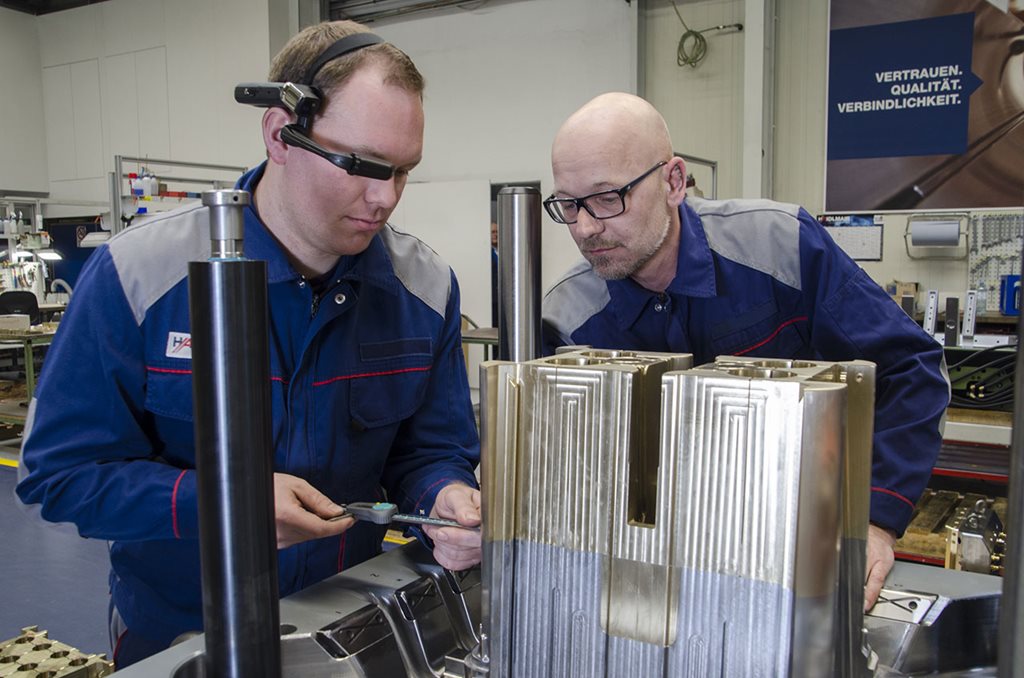

The future is digital, sustainable and innovative. In the world of Industry 4.0, the digitalisation of production forms the breeding ground for ideas that fundamentally change manufacturing and digital manufacturing. Modern technologies make it possible to design products and processes more efficiently and remain competitive.

Resilience is a key success factor here. Digitalised production processes can be flexibly adapted, accelerate workflows and make companies resilient - even in times of crisis.

But innovation and digitalisation alone are not enough. Transparency creates trust along the supply chain and within the organisation. Automation and digital twins visualise processes and enable efficient control of production.

Efficiency is also crucial: by optimising production processes and making targeted use of digital technologies, resources and capacities are used optimally - faster, more cost-effectively and more sustainably.

Together with our customers, we are shaping the industry of the future: digital, innovative, resilient and efficient. The digital transformation in manufacturing starts now.

-1920x1021.jpg)